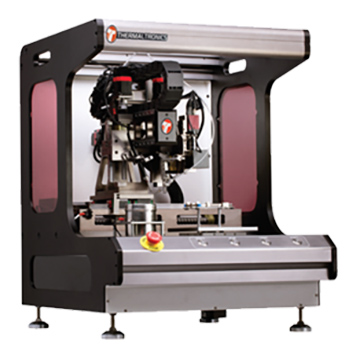

- Six Axis Soldering/Dispensing Platform

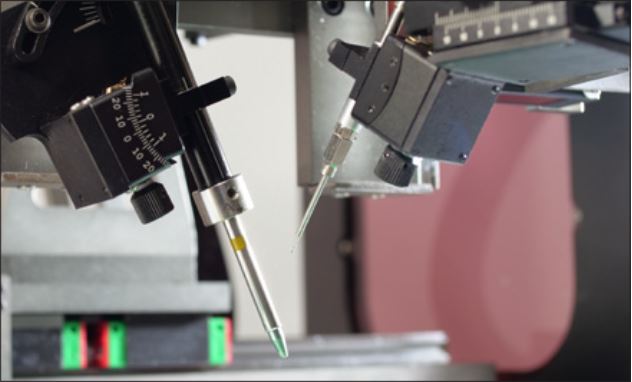

- Full vision mapping & Fiducial Marks

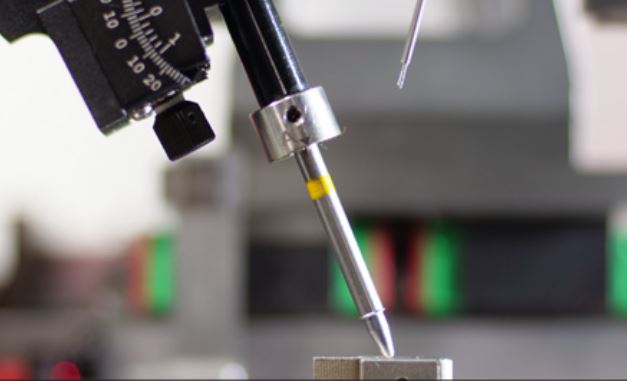

- Laser Height Measurement

- Curie Heat Technology provides precise temp. control

- Flux & Solder Paste dispensing

- Fume extraction

- Desoldering (Optional)

- Nitrogen Protection (Optional)

TMT-R9800S FEATURES

Unlike typical Cartesian robots the Thermaltronics Robot, Model TMT-R9800S, is equipped with full vision, (eyes) to verify the procedure being undertaken and does not simply follow a pre-determined program. In this respect it has an observation mode, a verification mode and as a result – a decision making capability. (Basically a brain). This capability of collecting and utilizing data for production processing is one of the most important factors necessary to meet the requirements of Industry 4.0 standards. Through the use of servo motors and precision ballscrews, the Thermaltronics Robotic system is able to accurately meet the requirements of high speed operation, repeatability and durability. The software is designed to transform system commands into functional operating procedures and with its 6-axis capability, 360° independent fixture rotation, solder tip and solder wire feeding operation from separate axis control, the applications extend beyond conventional soldering and dispensing operations.

Application programming is made simple by using full image-merging and mapping techniques. Dynamic laser height measurement/adaptive control, ensures precision soldering repeatability. A full vision mapping system with fiducial marks, provides for intelligent decision making during procedural operations.

- Identify a candidate for the soldering robot.

- Send us photos of the board/components and briefly describe customer requirements.

- Thermaltronics will review and advise on the application.

- If the application is suitable for robot we will ask you to provide sample parts to us.

- Thermaltronics will create the program, undertake the soldering and provide a video of the process and sample parts back to the customer for inspection.

- If the customer is interested - we can proceed to the next level of support.

- Through-hole applications

- Connector pin applications

- Enclosure applications

- Panel applications

- Final assembly applications

- Tinning applications

- Board on board applications

- Precision timing applications

- Circular soldering applications

- Wire applications

Clearly, there has to be a qualified operator within your organisation, otherwise the advantages of our system will be lost – but from experience, this process has the highest success rate.

Contact us here for more information

Magyar

Magyar English

English